So this one gets electrical again. If you compressor turns on and the low side pipe going into the firewall of the engine compartment is getting cold (around 30-40 degrees), and you are not getting the same temperature air out of the dash vents, then you have a vent, ducting, or fan problem.

If you have air flow, but it is not cold, check the blend door for operation first. There are a number of “doors” that direct the airflow of your HVAC system.

- BLEND DOOR: Directs the flow of the hot and cold air.

- MODE DOOR: Directs the direction of air, i.e., defroster, dash vents, floor vents, etc.

- RECIRC DOOR: Directs the fresh air in or recirculating the cabin air

These are controlled by electronic actuators that when commanded, turn the door to direct the desired air flow combination. If you have ever heard a soft knocking noise coming from under your dash, it was likely one of the air door actuators. These can fail on the mechanical side as well as electrically. See image below. You can try listening under the dash inside of the vehicle for any noise when turning the control from hot to cold. You will need a diagram of parts location and a wiring diagram to perform testing on these actuators. The blend door actuator is most of the time at least accessible for testing, but sometimes removal of the dash is necessary for replacement. Use a test light or power probe and verify that the proper signal is being received to the actuator based on your wiring diagram.

If you are getting no air flow at all, or low air flow, you may have an issue with your fan circuit. First thing is first, check your cabin air filter if equipped. Make sure that it is not clogged, or has come apart and lodged itself in the fan assembly. Replace cabin filter and clean fan from debris as required.

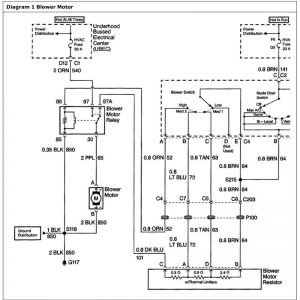

The fan circuit for most cars is pretty straight forward. Your controller sends a signal (power or ground) through a resistor, then through a relay, and then to your fan motor. A lot of newer cars, especially those with any kind of automatic air settings, these signals go through a computer also. We will be using the straight forward system as an example here. See the diagram below.

Find the Heater & AC Controller in the center of the diagram. Look at the blower switch. As you turn the switch from low to high settings, power is sent to the resistor unit. For every speed step up, the power signal goes through one less resistor inside the unit, thus supplying more voltage to the fan motor to turn it faster. Notice that full speed bypasses the resistor all together and triggers the relay to supply full 12V to the fan motor. Full 12V and full ground will give you the max speed the fan can go.

Start by testing all fuses that are related to you HVAC system. For testing, you will want to gain access to the fan motor plug and the resistor plug connectors. Most vehicles, this is located directly under the passenger side dash or behind the glove box. If the fan works on high speed only, then you know that you have a bad resistor. You will want to make sure that the connector hasn’t burnt out as well. Replace resistor and connector as needed. If no speed works, you can check the power and ground to the fan motor. If power and ground are present, replace the fan and connector as needed. If you have ground, but no power, you can supply power to the power side of the plug and make sure that the fan turns on. If it doesn’t, you will need a new fan motor, but you need to continue testing the resistor and controller. Test for your signal to your resistor. Look at the resistor in the diagram above. In this example, you will need to test each wire for a power signal with a voltmeter or power probe. You will be testing for voltage at each of the input wires. In this example, you will get a full 12V at each wire when that speed is selected from the controller if the controller is working. Test the BRN wire first on the lowest speed. Move to the TAN wire and the next speed setting on the controller. Perform this test through the remaining speeds and wires. If you are getting the signal at each input wire to the resistor, but no voltage out, then you will also need to replace the resistor. Always, inspect connectors when replacing these items. It is not uncommon to find burnt or deformed connectors when resistor or motor failure has occurred.