We have all had it happen to us. We’re driving down the road, singing our heart out to the song on the radio, when the little amber icon on the dash suddenly appears. You scratch your head, thinking “that light looks familiar. I know I’ve seen it somewhere before.” So you take it to your local mechanic and tell him the sad story and ask him to let you know what the problem is. He informs you that there is a diagnostic charge (most shops will tell you around $100 plus or minus $10-20) to pin-point your issue. To which the most common reply is, “Why do you charge so much to plug in your computer and tell me what it is?” Well, I am glad you asked.

I am not sure when or where the idea arose that when your check engine light comes on that all you need to do is plug in a scanner and you’ll have your answer, but unfortunately it is not that simple. I imagine that the free code scans, or “free check engine light diagnostics” as the parts stores like to call it, is where it started. The parts guy comes out to your car as if they have this magical device that will let you know everything that’s wrong with your car, ready to sell you whatever is on the top of the list of possible problems with your car. “Well Sir/Ma’am, looks like you have a misfire code. These spark plugs and wires should fix it!” the man at the counter exclaimed. My favorite is when they sell you a gas cap with the confidence that it’ll fix it, after only reading that you have an evaporative code. What they fail to educate their customer on is that these are merely possible cures to their issues and not guaranteed solutions. Remember, their job is to sell you parts. An automotive technician’s job is to fix your car.

“How to know if you have a good mechanic.”

Now, before I go into what it actually takes to tell you why your check engine light is on, I will tell you a little more about what a DTC (Diagnostic Trouble Code) is. First of all, your check engine light will always come on for some reason or another. “But I’ve replaced everything in that system and the light is still on,” you tell me. Well you replaced everything except the part that is bad or you did something wrong along the way. There are a number of sensors that monitor your vehicle’s emissions system. Well, sensors monitor just about everything on your car, but we are talking about your check engine light which is strictly for your emissions system. Some of these sensors tell your Engine Control Module (ECM) if a different air to fuel ratio is needed for the current driving condition or if a certain system isn’t performing within the required specifications. Sometimes there is one sensor monitoring an entire circuit that consists of many different components and other times there are a number of sensors monitoring each part of a circuit. The more sensors on a circuit means the more accurate the code will be to narrowing down your issue. But that also means more parts that can break or fail costing you more in potential repairs.

When your check engine light comes on, here is the process that a technician has to go through to pin point your problem:

- First, they will scan for DTC’s and verify any drivability complaints.

- Using his or her knowledge and years of experience, they will check for obvious faults that could lead to your codes such as loose or broken wires, rotted vacuum lines, or unplugged sensors or electrical components.

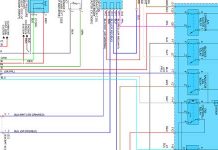

- They may need to monitor PIDs (Parameter ID’s) on their scan tool and see what all the sensors in the faulty circuit are doing and how they are talking to each other.

- Now, the often time consuming part, running tests. After gathering all of the preliminary data, the technician will pull up wiring diagrams and check tech forums (both of these come from costly monthly subscription services that most shops/technicians pay for) and come up with a logical flow chart for testing the circuit. Sometimes these test procedures are very quick. Some are extremely time consuming, some times to the point that your service advisor may call and request more money for more diagnostic time.

At the end of the testing, the technician will have found a single (sometimes multiple) failed part(s) and will advise you to replace those things and then recheck the system. That’s right, recheck the system. Sometimes, the first failed parts found are merely a starting point.

The point is, getting your check engine light codes is a single step in a very complex and time consuming procedure to find out why the light is on in the first place. To get the right answer for your problem it involves using expensive equipment and knowledge gained from schooling, classes, or years spent fixing cars. Not to mention the overhead of the shop you brought your car to. You pay your doctor without a second thought when you go into his office with a cold, for him to just say, “Yup, you have a cold. Get rest.” Automotive technicians are arguably the same as physicians, but for your car. I wish that there was a single device that could tell you everything wrong with your car. I imagine that someday, likely in the not too distant future, cars will be smart enough to pinpoint exact failures, but for now, you will have to rely on the knowledge and experience of automotive diagnosticians.

Nice article Jared. I will keep this booked marked and share it with our service writers so they can explain the process better to our customers that ask..

There are definitely parallels between auto repair and practicing medicine, especially when it comes to diagnostics. I often compare us to pediatricians. Kids are not always capable of explaining their ills so the parent does. Vehicle’s can’t necessarily tell us what is wrong, but the drivers (parents?) do. DTCs give us either very precise direction for what a given module/system does not like seeing or in some case a very general direction.

We then use different equipment to gather data. We have scan tools, pressure gauges, DSOs (with assortments of transducers) and exhaust gas analyzers. Doctors have pressure gauges, EKGs, CT and MRI scan to help them as well.

Maybe we just need to push through a national vehicle care insurance package?

Interesting article, but it’s rather ignorant about what’s really going on. Enough so, that you really couldn’t be more wrong in some of the things you’re stating.

Let’s begin with the most obvious. Garages exist to make money, just as parts stores exist to sell parts. Garage repair manuals also embellish the time involved in repairing various parts on a vehicle, and when auto shops charge $120/hr, people aren’t willing to pay 1.5 hours of labour for a job that in reality takes 0.75 hours.

Most people, who are looking to have a code retrieved are going to do the work themselves and aren’t interested in paying for “diagnostic” charges to have someone do a five minute job.

Furthermore, code readers on the market today do more than just retrieving codes. Autel, the manufacturer that actually builds and develops the “very expensive” equipment that you use, puts the same software into consumer level equipment, with updatable software. Sure, the $250 tool doesn’t do everything that the $2,500 tool does, but it will pull the codes and provide the backyard mechanic with the exact same information that the mechanics will get at the garage. They’re going to look at all the wiring, hoses, plugs just as the diagnostician would, it is the most logical first step in fixing something.

The most common part to go on newer cars that give an EVAP error is the gas cap. Most will tell you to go reseat your gas cap and check the rubber on it for damage after resetting the code. If the gas cap is damaged, replace it. If not and the code comes back, then a deeper look is needed. You accuse the parts shop of just wanting to sell you a part, but the fact is, you’re going to follow the exact same procedure. It’s in the manual, after all, and all part of that common sense thing I mentioned earlier.

Say your vehicle gives you a P0300 code. Multiple Misfire. The Autel 519 Code Reader tool, will not only give you the code, but has the software to look at each individual cylinder and will tell you which one is misfiring, all in less than 10 minutes.

Let’s take your “maybe in the future” comment about cars pin-pointing the exact problem and your “gas-cap” scenario. For about the last five years, vehicles have OBD tools that will actually separate the CEL from the Check Gas Cap light, and even some that will distinguish an EVAP concern separate from the CEL. For example, a 2011 Honda CR-Z will give you a MIL telling you to check the gas cap. Honda wasn’t the first to equip their vehicles with this coding, so the technology to pinpoint already exists.

Information is available on the internet, on forums, even ones that don’t require subscriptions.

Todays diagnosticians don’t use their experience, they follow the book. When they’ve run out of ideas and the book isn’t resolving the problem, they contact the engineers to see if they have any ideas. This method, is costly. No one wants to jump ahead, they want to follow the book in the same fashion a pilot follows his check list. In the meantime, a recurring problem has now cost the vehicle owner $800, with every EVAP sensor replaced and the problem still isn’t fixed. In the meantime, Johnny parts seller, who actually has experience tells the owner, “When was the last time you changed your air filter?”. What do you know… the air filter, in this particular case on a 2010 VW Jetta was the problem. A problem, the diagnosticians couldn’t figure out.

The POINT is, the problem isn’t always complicated and it doesn’t require expensive diagnostics and visiting a mechanic is more like visiting your local computer repair shop. Sometimes the simplest fix is what’s causing something that appears to be more serious. Comparing it to the medical profession, is more of an insult to those who have to take into account what happens on a molecular level.

If you think the over the counter scan tools tell you “the exact same information” as the $2500 tool does, you are the ignorant one. You have obviously never worked in a successful garage to say that labor guides embellish repair times. Those times are pretty accurate most of the time (it goes both ways. some are less, some are more). The job gets quicker as the technicians skills get better. Are you suggesting that technicians should get paid less as they get better at their craft? Lastly, I think that it is people like you that put these thoughts in the general public’s heads that diagnostics is a “5 minute job”. Don’t worry though, we will continue to fix your shade tree diagnostics after you have guessed at all the possible causes and spent all your friends money on your inexperience. Thank you for writing this article, but unfortunately, some people cannot be taught the right way to do things.

There’s a whole lot of ignorance and arrogance in your post, but let’s rip it apart much like I ripped apart your article.

There’s a difference between a $69 tool that just gives you a code, and a $600 tool that has the exact same core software that your $2,500 tool has. Using your own logic, I could say that the $2,500 tool isn’t going to do diddly against the $15,000 tools that are out there. Typical arrogant statement from someone who doesn’t have a clue how software is developed.

This notion of “a mechanic gets faster as he gets more experience” is as ludicrous as your original post, so lets cut the crap. The laws of physics and time don’t change simply because you got better at your job. All “getting better at your job” means is that you’ll make less mistakes.

Considering mechanics who’ve been at the job longer than you were a sparkle in your daddy’s eye have said that the books are embellished, I’ll have to take their word over yours. Being a “successful” garage has nothing to do with it. What’s written in the book is what’s written in the book.

Let’s give you a real life example. 2000 Jeep Grand Cherokee has a failing power lock actuator. Book time, per Chrysler LLC, 1.5 hours. Actual time? 0.75 hours.

But hey… let’s put your “experience” to the test. I have a 2012 Volkswagen Routan that has been problematic for the last seven months. Since it’s under warranty, it’s been brought to the dealership for repair each time the CEL has illuminated and each time the engine “stalled” without warning or illumination of MILs.

The same two P codes have returned. P0018 and P0300. All diagnosed on your precious “only a mechanic such as myself has access to such software” diagnostic systems. Well over $6,000 has been spent on diagnostic charges alone. Spark plugs have been replaced, not once, but twice. ignition coils have been replaced. Camshaft sensor associated to P0018 has been replaced three times, not including a swap with a known working sensor. Cam phasers have been replaced. All wiring has been reviewed by three separate mechanics, one of which deals explicitly with troublesome vehicles for major manufacturers, including Mitsubishi. Every known possible issue in the same books you have access too, have been exhausted, yet no one can figure out what’s wrong with it. TIPM software has been updated and all recall notices have been examined.

Here’s the best part. All the information that they’ve given me, I’ve been able to obtain from my tool. Including which cylinder has misfired. Suck it up buttercup, some of us actually know more than you think we do.

Buttercup, cute. First of all, I did not write the original article and you didn’t rip apart anything except your credibility to speak as a knowledgeable automotive professional with your comments. I’ll start with your VW issue. I never said that a scan tool tells you everything, that is where knowledge comes in. It is obvious that what ever the issue is with that car is an intermittent issue and possibly they have never gotten it to fail while they are testing. Of course I am speculating since I don’t have access to your car, but the point is that although a bunch of things were replaced, the failing part still remains. Second, your cheap scan tool will point out specific cylinder misfires when that DTC presents itself. Some may even have a PID to monitor each cylinder misfire counter. But not all cars have that perimeter set in the PCM, i.e., Ford company, you need to access mode $06 to see each cylinder. I’d love for your scan tool to show me the SOC of each battery cell in a Hybrid vehicle. Can it relearn the yaw rate or the brake pedal stroke simulator on a Toyota. How about the CKP sensor on a GM? Maybe something a little more particle for you since you obviously understand how evap systems work, why don’t you try running an evap pressure test with your scanner. Nah, you’d rather just advise to replace the gas cap. The more expensive scan tools can access vehicle specific PIDs and perform more tasks where your little scan tool can likely only access Global information. More money equals better software. And that is coming from someone who is currently programing a mobile application to interface with an OBDII dongle for a very big company. So if you want to talk about software development, I will be more than happy to dive into that subject with you. Lastly, your book time comment. If you read the labor guide correctly, each job has a tech level assigned to it. The labor time is given based on the minimum level of the technician’s EXPERIENCE required and the amount of time that it should take that level technician to complete the job. More experienced technicians can get the job done faster in most cases because they know each step to the job and what tool they will need next therefore reducing the thinking/planning time to perform the job. I am glad that you can do a door lock actuator in a Jeep faster than the book time calls for (which is only .9 according to Alldata). Maybe you should be a technician since you are so good.

Whatever helps you sleep at night. You didn’t provide credit of whomever wrote it, so let’s not start back tracking now.

I didn’t “rip” my credibility apart, although you further damaged yours with the backtracking of who wrote the article you posted. Not to mention the double talk that’s going on in this reply. Make up your mind.

You’re making assumptions about what they’ve done with my VW issue. First of all, anyone who’s so mechanically inclined as you claim to be, would know that the Routan is fully manufactured by Chrysler Group LLC. Secondly, the failures have been replicated while it was in the garage. You can “speculate” all you want, but you were given everything, and it any “experienced” technician would know that Chrysler has had faulty TIPM since 2007.

The point is, that while a lot of parts were replaced, the “expert technicians” like the type you’re claiming to be, would rather replace parts like shooting int he dark and when that fails, replacing the same part multiple times all the while ignoring the owner who actually did some research and saying “Hey, did you know that the TIPM in these vans are failing a lot, did you check it?” and experts such as yourself say “Oh, it’s not that” without actually checking it?

BTW, my “cheap” tool, doesn’t require the specific DTC to point out the misfire. So, clearly you’re talking out your ass once again, since the extended crank, in my case is caused by a misfire in cylinder 1, and it doesn’t throw a DTC. How about you actually take a look at what “my little scan tool” can do before you continue to present yourself a fool. Nah, you wouldn’t want to do any research, instead you’d just want to embellish your “extensive experience”.

Instead you’d rather throw around terms (BTW, mine does read the DOD on my hybrid Honda) you likely found on the internet. As for the gas cap issue? Considering most cars today tell you to check the gas cap, that would be rather irrelevant for me to use my tool, wouldn’t it? I mean… you probably already knew that most cars today tell you to check the gas cap, since you’re an “expert” and all.

Oddly enough, my Honda had an issue where both the check gas cap light and the engine light came on. Funny thing is, it only did it when the tank was 3/8 full. I mentioned all of this to one of you alleged “experts” who look at it for all of 3min and said that it was the gas cap and reset the code. Had to go back the next day, chew out both the SM and the mechanic, after MY “little tool” found a fault with the EVAP system and required a replacement.

Now, laughably, after claiming to be an expert mechanic, you’re claiming to be an “expert software developer” creating mobile application for “a very large company”? Give me a break. Aside from the fact that I’ve already done that with a laptop, and built my own dongle in 2001, there are a multitude of mobile applications that already exist. You know, like OBDSoftware, OBDAutoDoctor, OBDKey, ScanTools, etc., etc., etc..

Congrats, AllData says 0.9 hours. Still longer than someone who did it in 0.5. I’ve read the guide properly, but maybe if you’d bother pulling out head out of your ass, instead of talking out of it, you’d realize that not all “experts” know what they’re doing and the article “you didn’t write” was full of shit.

If you can’t tell the difference between the name of the person who posted the article and the person replying to you, I doubt your ability to analyze the diagnostics of anything.