Now that we have the refrigerant at a known good level and the compressor is still not coming on, we will need to check power and ground to the system. If you have not verified freon levels, you need to start there before going straight into electrical. Follow the link below to see how to check your freon levels:

You will need a test light or power probe for this part of the testing.

You will need to find the signal wire connector that attaches to the compressor clutch. This is most of the time located on the side or top of the compressor and is typically 2, sometimes 3, wire harness. Check for power AND ground to the compressor. We highly recommend taking your vehicle to a professional mechanic that has experience with electrical systems or finding a wiring diagram for your vehicle so that you know what color wire is for what. You can request one for your specific vehicle through our Ask A Mechanic section HERE. DO NOT SUPPLY DIRECT POWER OR GROUND TO A WIRE IF YOU DO NOT KNOW WHAT IT DOES. You can cause serious damage to your vehicle.

That all said, if you find that you have power and ground to your compressor clutch and it still does not turn on, then you have a bad clutch. You can replace just the clutch in most vehicles, but I personally recommend replacing the compressor as a whole. Whenever you replace your compressor or have the system open for an extended period of time, it is also wise to replace the accumulator, or receiver/drier depending on your A/C type. This piece of your air conditioning is meant to collect the moisture from the system and keep it away from crucial parts like the compressor and/or expansion device. It also acts as a filter that protects the compressor from debris.

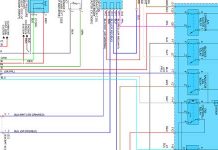

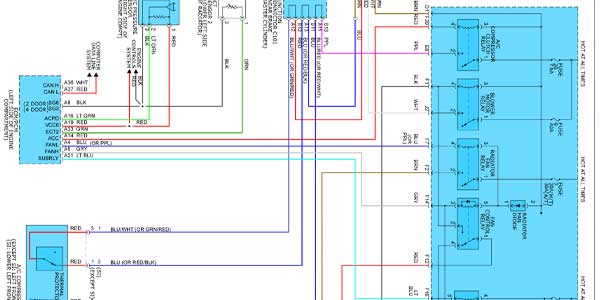

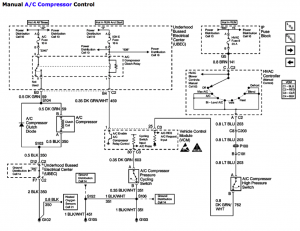

If you do not have GROUND at your compressor, you will need to trace the ground back and find out where it is broken or shorted. Looking at the diagram below as an example (this is for a manual A/C system from a Chevy Truck), you can see that the black (BLK) wire from the compressor depicted on the left lower portion of the diagram is the ground and runs through a ground distribution cell before grounding to the the frame or engine at G102. Once you find the fault, repair and retest.

If you do not have POWER at your compressor, you will need to have a good understanding how your system works in order to diagnose it correctly. There are a few different devices that power may have to travel through or from in order for your compressor to receive the signal. Typically, the command starts at the switch inside of the cabin which will normally send power to a pressure switch. As long as the pressure is good in the system and the switch is good, it will send power to either a computer like your BCM or ACCM which will then send power to a compressor relay. Sometimes, like in the diagram above, there are other switches and sensors that send signals to the computer that can tell it the A/C system is not safe to operate due to some other part of the system being out of parameter, like cycling switches, fan switch, evaporator temperature sensors, etc. If all parameters are met, a signal is sent to the A/C compressor clutch relay which then forwards power to the compressor, engaging the clutch for operation.

So understand your system before you start testing. You can request assistance with our Ask A Mechanic section of Car How To HERE. Start by checking all fuses that are related to your air conditioner. Be sure to look in both the interior fuse block and the underhood fuse block. For testing the circuit, you will want to imagine each part of wire in between each device as its own section that you will be testing. For starters, you can verify that the wiring is good from the relay to the compressor by removing the relay and jumping power to the exciter circuit and see if the compressor comes on. If it turns on, you know that that part of the circuit is intact. Then see if you are missing any of the other signals from the relay plug. If you have all the signals, then you know you have a bad relay. Find the signal on the wiring diagram that you are missing at the relay and continue to follow it back.

You can next try jumping the pressure switch(es) to see if you can get the compressor to operate. Take caution when doing this as you can cause damage if you are not familiar with how your AC electrical system works. You can remove the connector for the pressure switch and check to see if you have power at either wire. If you do, you can use a paperclip or small gauge wire as a jumper to complete the circuit and bypass the switch. If the compressor comes on, you now know that you have a bad switch (remember that we already confirmed that the system is filled to the proper level). If you do not have power at the switch, you can keep tracing down the circuit to find the fault.

You will need to check the signals coming from the control unit inside the cabin now. Most of the time, this will require removing the control unit to test. Once you have access to the control unit wiring harness, verify that you have power and ground to the controller, and that you have the proper signals coming out of the unit. If you have the power and ground to the unit, and are missing the signals out, replace the controller and retest. If you have all signals correct, you will need to check the signals going in and out of the computer at the computer. These can be power or ground so you will need a connecter view diagram and the wiring diagram to know which wires to check.